A State at the Heart of India’s Dairy Economy

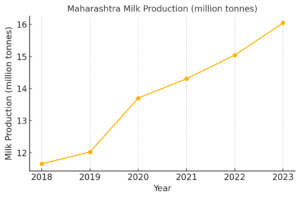

Maharashtra, often celebrated as India’s sugar bowl, is equally a powerhouse in dairy. Contributing over 16 million tonnes of milk annually, the state accounts for around 6–7% of India’s total milk production. From the bustling markets of Mumbai and Pune to the drought-prone districts of Marathwada, milk is more than a staple—it’s a lifeline.

Yet, this success is not without its challenges. Seasonal swings, erratic monsoons, and fodder scarcity frequently test the resilience of Maharashtra’s dairies. Flush seasons (September–March) bring surpluses, while lean summers strain supply. The intensifying impact of climate change—drought one year, floods the next—demands a forward-looking approach to procurement, feed security, and processing infrastructure.

Gokul (Kolhapur District Cooperative Milk Producers Union Ltd): A

Founded in 1963, Gokul Dairy has become a hallmark of cooperative strength in western Maharashtra. Today, it handles an average of 1.6 million litres of milk daily, scaling up to 1.8 million litres in the flush season. Through a network of 7,000+ village societies, Gokul serves over 500,000 farmers and commands an impressive 86% market share in the Kolhapur district. Gokul was among the early adopters of the Ethno-Veterinary project, which has benefited over 93,000 farmers by improving animal immunity, reducing dependence on antibiotics, increasing milk yield, and ensuring safer milk production. Additional services include deworming camps, vaccination drives, free infertility camps, animal nutrition programs, and calf-rearing schemes—creating an ecosystem where farmers receive consistent and reliable support. Notably, Gokul has pioneered climate-smart practices, such as establishing Maharashtra’s first fodder bank and installing over 7,000 biogas units—reducing per-unit installation costs from INR 43,000 to INR 5,000 through subsidies. It also operates a 6.5 MW solar power plant that supplies energy for its operations. Another key innovation is the slurry project, which produces organic fertilizers. Gokul’s product portfolio balances staples with tradition, offering ghee, butter, dahi, paneer, shrikhand, and the iconic Kolhapuri pedha. With an annual turnover nearing INR 40 billion (~USD 480 million), Gokul exemplifies what’s possible when professional management is paired with farmer-first governance.

Chitale Dairy (Sangli): Technology at the Service of Farmers

If Gokul represents cooperative strength, Chitale Dairy is a story of private innovation.

Since 2015, over 50,000 animals in its network have been fitted with RFID collars, which feed data into a cloud platform that tracks their health, productivity, and breeding. Farmers receive SMS alerts on animal health, while supply chain orders are managed digitally, ensuring traceability “from cow to cloud.”

A strategic partnership with ABS Genus has turned Chitale into one of Asia’s most advanced buffalo breeding centres, producing 50 million doses of high-quality semen annually. Productivity has soared: households once producing 2–3 litres per day now reach 8–10 litres, and herd sizes have grown from 4–5 to 10–20 animals per farm.

Beyond the farm, Chitale has embraced consumer innovation. During the COVID-19 pandemic, it swiftly rolled out a home delivery app, leveraging its IT backbone to keep milk flowing in Pune and Mumbai. Its product range, including milk, ghee, butter, paneer, cheese, shrikhand, and SMP, remains synonymous with premium quality.

Chitale proves that data-driven agriculture, genetic advancement, and farmer empowerment can coexist—delivering productivity without ecological strain.

| Dairy (Location) | Structure | Daily Capacity | Farmer Network | Technological Highlights | |

| Gokul (Kolhapur) | Cooperative | ~1.6 million L/day | 5+ lakh farmers via 7,500 societies | Veterinary network, fodder bank, solar & biogas | |

| Chitale (Sangli) | Private | 1 million L/day | 50,000+ farmers, 2 lakh+ cattle tracked | RFID collars, cloud data, genetics lab (ABS JV) | |

| Sonai (Indapur) | Private | 3.5 million L/day | 5 lakh farmers | Automated mega-plant, casein & whey processing, export orientation |

Sonai Dairy (Indapur): Industrial Scale Meets Farmer Trust

From a modest 12,000 litres two decades ago, Sonai now processes ~5 million litres of milk per day at a single Indapur site — the largest such private facility in India. Daily outputs include:

- 300 tonnes of SMP

- 150 tonnes of butter

- 60 tonnes of ghee

- 250,000 litres of pouch and UHT milk

Sonai’s strength lies in scale, diversification, and export readiness.By investing in advanced spray dryers, cheese units, and whey protein plants, it’s tapping into global dairy demand. Casein, lactose, and whey proteins are now part of its export basket, with markets in North America, the Middle East, and Asia-Pacific.

Equally, Sonai has remained farmer-centric. Over 500,000 farmers, both directly and indirectly, benefit from timely payments, feed access, and veterinary care. Its success has turned Indapur into a rural industrial hub, spurring jobs in logistics, packaging, and allied sectors.

Lessons for Policy and Practice

Maharashtra’s dairy sector offers a blueprint for India:

- Cooperatives like Gokul prove the enduring power of farmer-owned structures.

- Private innovators like Chitale show the transformative potential of technology and genetics.

- Industrial giants like Sonai highlight the importance of scale, diversification, and exports.

For policymakers, the message is clear: invest in fodder security, incentivise value-addition, expand genetic programmes, and foster cooperative–private complementarities. For dairy professionals, the case studies reinforce that India’s future lies not only in producing more milk, but in producing better, traceable, and higher-value milk products.

Maharashtra, with its rich tradition and cutting-edge innovation, is not just a dairy state; it is a microcosm of India’s dairy future.